Piping and Vessel Flange Integrity Assessments and Remediation Solutions

A descriptive paragraph that tells clients how good you are and proves that you are the best choice that they’ve made.

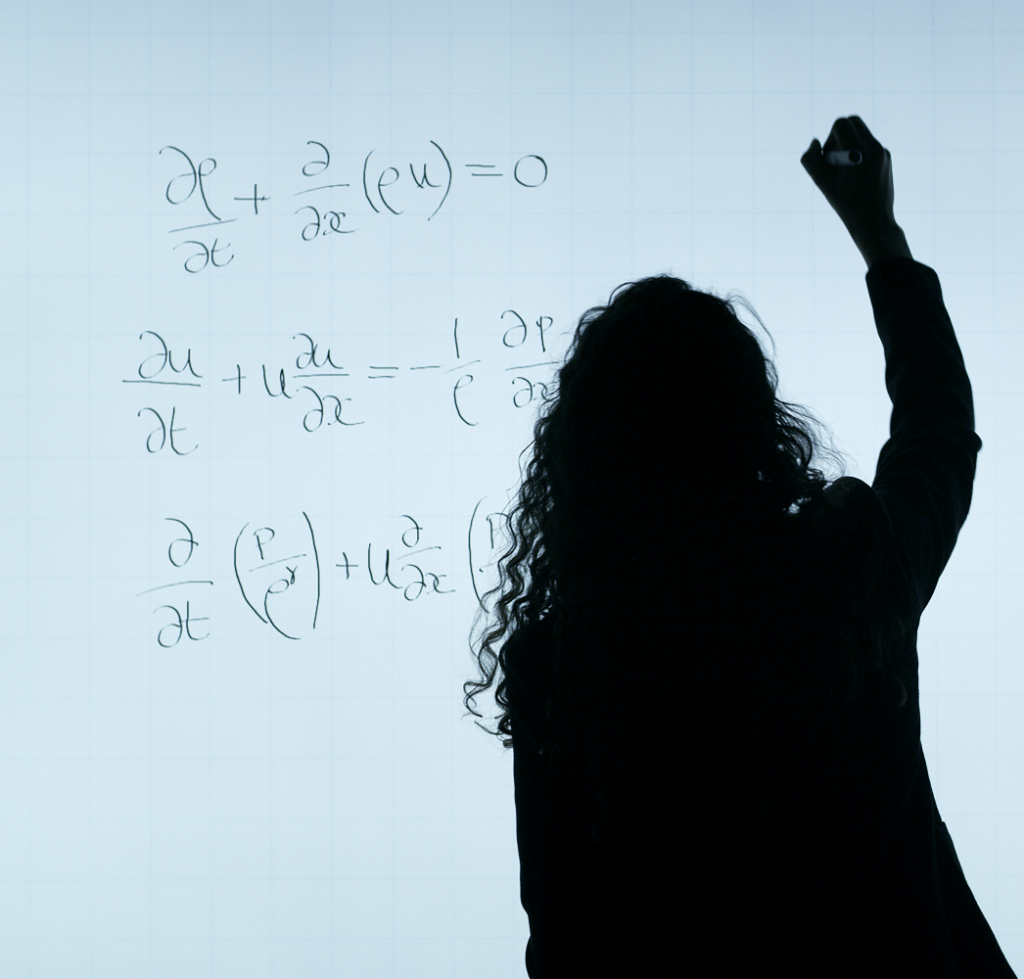

Advanced, Modern Training.

A descriptive paragraph that tells clients how good you are and proves that you are the best choice that they’ve made.

over 40 years flange design

and analysis experience

Advanced Comprehensive Training Solutions, LLC personnel have over 40 years flange design and analysis experience specializing in high and extreme high temperature applications. Today’s industry efficiency requirements are driving process temperatures and pressure higher and higher. The ASME B16.5 flange was originally designed in 1895. Until recently, temperatures below 500 ºF were common and the ASME B16.5 design was not challenged. However, temperature above 1400 ºF are not uncommon and the ASME B16.5 design cannot adequately handle these extremes. The result is can be loss of seal integrity at start-up and shutdowns, thermal cycling of the process and finally, full design failure over time.

- COURSE LINK

- COURSE LINK

- COURSE LINK

- COURSE LINK

- COURSE LINK

Low cost training to equipment maintenance engineers and managers with Fitness-for-Service expertise at a time when such training will be basic for continued plant operations and maintenance.

With renewed focus on alternate energy, Fitness-for-Service expertise will be prominent in the continued operation of aging refineries.